Agri-Stor Companies www.agri-stor.com

Agri-Star Control Panel

Agri-Stor Companies helps growers take control of their onion storage with Gellert’s Agri-Star Control Panel. Since 1964, Agri-Stor has designed and sold thousands of Agri-Star panels for a wide range of post- harvest products. Through these years of application experience and university-based research, Agri- Stor Companies has developed its most user-friendly, advanced control panel yet. Features include a full-color, interactive touchscreen, easy-to-understand programming and internet capabilities with an intuitive app.

Fully adaptable to growers’ onion storages, the Agri-Star panel can handle everything including curing mode, burners, humidity, refrigeration, airflow, temperature, carbon dioxide levels, heat and lights. When growers match the Agri-Star panel with Gellert’s climate control equipment, their onions are wrapped in the perfect climate, extending their life and quality.

Greentronics www.greentronics.com

RiteTrace

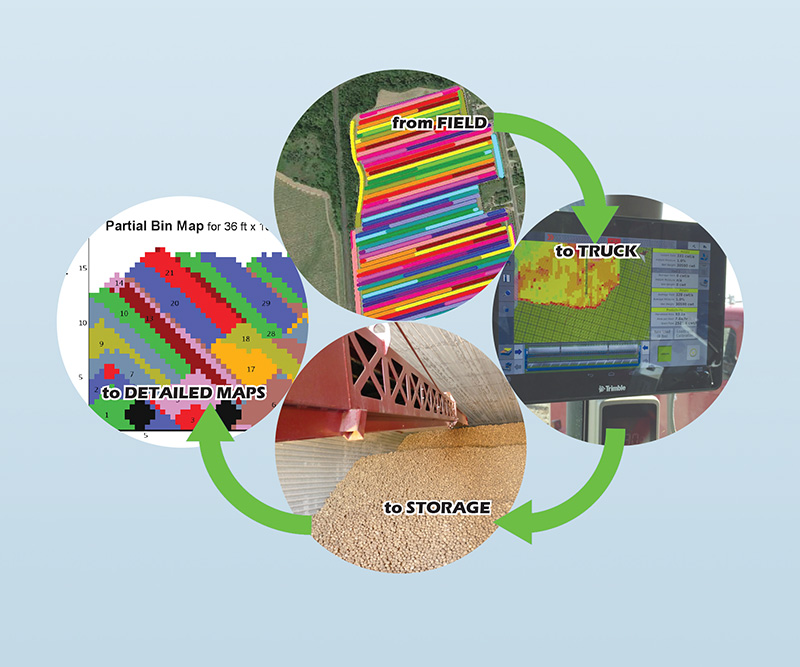

Greentronics has added load-by-load field-to-storage tracking to its RiteYield root crop yield monitor product. The new product, RiteTrace, is designed to automate harvest and storage data recording. This provides onion growers with a wide range of reports as well as field and 3D storage maps detailing where each load originated and is stored. Maps allow growers to link areas in storages and fields to better understand quality issues and improve crop management discussions and communications with buyers and processors.

Reports include yields by variety and field, and loads by field, storage and truck. Data points are date/time stamped, and maps and reports work well with GAP compliance.

Greentronics offers yield data integration with John Deere GS3 2630 and Trimble FMx and TMx monitors, allowing operators to view yield maps in real time. Yield maps offer visual insights to yield variability across fields and farms. Data are useful in calculating nutrient removal and generating variable rate application prescription maps.

Lee Shuknecht & Sons, Inc. www.shuknecht.com

SP-132 Onion Harvester

Lee Shuknecht & Sons, Inc.’s SP-132 is a self-propelled two-bed harvester that eliminates windrowing while simultaneously direct loading two beds, for a total production width of 132 inches using 47-inch chains. The low-maintenance mechanical harvester provides the highest percentage of topping of all Shuknecht’s onion harvesters, harvesting two to three tons per minute.

Powered by a standard 190-hp Cummins engine, the solo operator seated in an air-conditioned cab has complete control over blower speed, primary and rear elevator speeds, cutter bar speed and height, and ground speed. The two-bed harvester features a 4-foot high-capacity boom and easily controlled front pickup elevators with spring assist floats.

The list of available options includes: a moveable 4-foot or 5-foot dipper, rotating cab, stainless blower housing liners and a 240-hp engine. Digital readouts for the blower, primary chain and ground speed can be included, as well as hydraulic adjustment front elevator gauge wheels. Ground sync primary chain control, a posi-traction four-wheel-drive system and hydraulic trash chain drive can all be built into the SP-132.

SYMACH www.symach.nl/en

Palletizers

SYMACH palletizers make onion operations more efficient and produce pallets with no product overhang. The machines offer immediate labor savings, prevent product damage, and stack neat, stable pallets every time.

SYMACH is now part of Barry-Wehmiller’s companies and continues to deliver products people need every day.

Synthetic Resources Incorporated www.syntheticresources.com

ReflectorNET

ReflectorNET is an elastic pallet wrapping net typically used in the agricultural business for palletizing fresh produce that requires ventilation. ReflectorNET is manufactured with enhanced elasticity to wrap more pallets per roll, which saves money on packaging products, and to allow for stronger pallet containment, which provides peace of mind that loads are securely wrapped. ReflectorNET saves 50 to 60 percent of the cost of strap-and-corners packaging methods. The product offers an aggressive built-in memory that helps maintain width, providing excellent pallet stability with only little overlapping whether used in a wrapping machine or manually. Synthetic Resources Inc. offers ReflectorNET in 20-inch- and 30-inch-wide machine rolls. Standard pallet netting is available in hand and machine rolls.

Top Air www.topair.ag

RL 8400

The RL 8400 is the latest and largest model of Top Air’s rod lifter line, designed to maximize the efficiency of tractors and manpower. Wing fold design allows safe and manageable road transport of the 8 x 44” bed model. Double rods are hydraulically driven by three separate drive standards, the standard configuration of four 7.6 – 15” gauge wheels provide consistent depth control, and Clymer spring-loaded coulters prevent buildup of leaves and debris on the standards. Available onion savers help keep onions out of the wheel tracks and on the beds.

Univerco www.univerco.com

Challenger

II Two-Row Onion Harvester

With 35 years of experience in building onion harvesters, Univerco has developed the Challenger model that has been successfully harvesting short-, intermediate- and long-day onions. The Challenger II has the same capability, but in a two-row version.

The variable-speed topper table will allow the operator to cut onion tops regardless of the quantity of onions going through the table and will also cut greener tops. Brushes under the topper table keep the rollers clean, and weeds are ejected by the table without affecting the onion flow. Smooth transitions between conveyors help keep a good quality onion, even in softer varieties. A steering axle that allows a short turning radius and a system of three cameras to monitor the key areas of the machine are some of the features that make the Challenger II Univerco’s most versatile onion harvester regardless of soil or onion type.