By Kyle Coleman, Director of Marketing and Commercial Development, NovaSource North America

More than four years ago, I wouldn’t have predicted the discovery of some assumption-busting revelations about the post-application movement and longevity in the soil of the fumigants metam sodium and metam potassium for the suppression of weeds, disease and nematodes.

But in 2017, I took the first soil sample readings of what is now a database of more than 40,000 readings to track what happens to metam products underground after they’re applied. The study involved soil sampling at dozens of locations in nine states across the U.S. in the hours and days following metam product application.

Today, with the help of coworkers and many custom applicators, we have a much greater understanding of how to enhance the efficiency and effectiveness of these proven products in a variety of different conditions.

Startling Revelations

Our quest for insights into how to maximize metam product performance began when I acquired a photoionization detector (PID) after learning of this technology from Dr. Steve Fennimore, a weed scientist at UC Davis, and researchers at other major universities. I had been working with metam products since 1999, but had no clue this equipment was available.

With the walkie talkie-sized unit in hand, I made a visit to a custom applicator to try it out. I only wanted to see how the technology worked, and I had no idea that my own longstanding assumptions were about to change.

The initial findings in that first field were startling. Metam fumigant had been shanked at a depth of 12 inches, and 48 hours later, there was almost no trace of the product found in the top 6 inches of soil. We were all perplexed by the findings and assumed the product in those top 6 inches had already dissipated or would make its way up through the soil profile with time. Many evaluations later, I realized how wrong I had been.

We found that metam readings peak where the product is placed, and both upward and downward movement occurs. But movement is limited and is subject to several factors.

Common Themes Emerge

I’ve seen single-level and dual-level placement, rototillers, drip application and chemigation. I’ve seen sweeps, shanks, nozzles and drop tubes in many configurations with more than 50 cooperators. I’ve been on soil that is so dry the dust shot up into my pant legs with every step, and fields so muddy I could barely keep my balance. Every single application method creates a unique pattern, and the conditions in which the product is applied create another layer of complexity.

It became apparent that we’d need to prioritize the pests being targeted, be more specific about pest location and determine how to get more precise about placing the product where it needed to be.

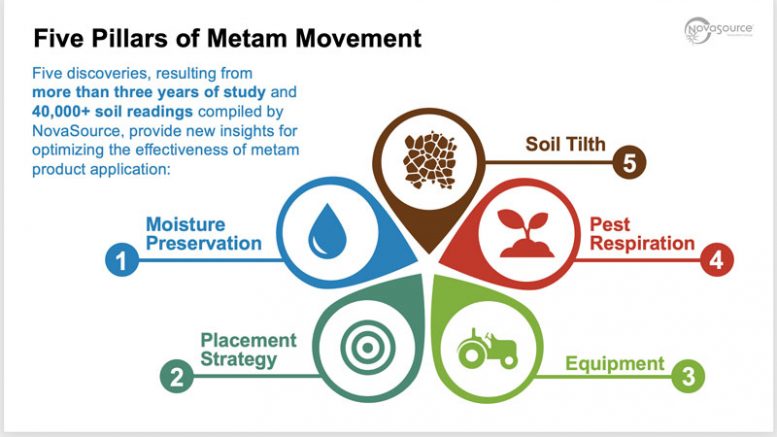

Now, the data we’ve collected reveals five primary variables that can create significant differences in product effectiveness – often, when only minor adjustments to an application method are employed.

I call these variables “the five pillars of metam movement in soil.”

Moisture Preservation

If possible, maintain 80 percent moisture throughout the soil profile weeks before application up to the day of application. Moist soil delivers several benefits: submoisture helps facilitate metam movement; moist soil promotes respiration in an important pest like weeds; moisture in the soil helps maintain longer exposure times; and from a stewardship perspective, moisture helps reduce odor and the chance of off-gassing.

Placement Strategy

Compared to other fumigants, the vapor pressure of metam products is relatively low, so they simply don’t travel as far or as uniformly as applicators have assumed for many years. Sampling the soil to better understand your exact pest location is recommended. Then, precision place your metam product near your targeted pests through chemigation, shanking or deep shanking.

Equipment

Making even minor adjustments to the equipment you’re using to prepare soil, apply product and seal the application can make a big difference. Know the precise and unique pattern created by your machinery. Roughing up the soil a little won’t compromise performance as long as you don’t dry it out or leave product on or near the soil surface.

Pest Respiration

Pests are living organisms. And metam products are most effective when the pest is most susceptible and the application is optimal. If you can’t imagine a weed seed really thriving in a certain soil condition, then it probably isn’t – and suppression is much more difficult.

Soil Tilth

Dry, compacted or cloddy soil can limit product movement. Avoid applying the product to deeply frozen soil. Anything you can do to avoid drying the soil is critical because the metam may dissipate in dry soil before it has time to do its job.

Case Study: Idaho Onion Grower

Here’s an example from the many case studies we have collected.

In this situation, nutsedge was becoming a devastating problem for the grower. Weed seeds were not respiring at the time of application due to a prolonged period without moisture.

Then, the grower began to moisten fields with canal water immediately after grain harvest up until the time of application. The depth of application was changed from 10-12 inches to 6-7 inches. These changes resulted in outstanding nutsedge suppression.

What Really Matters

Many operators are reporting improved results from making product application adjustments based on “the five pillars.” And while they’re all relevant to product performance, the consensus belief is that moisture preservation is the area that’s most important.

I often reflect back to 2012, when new use labels for metam products were implemented. Buffer zones drove the number of chemigation applications downward from 70 percent of all application activity to less than 30 percent in the Pacific Northwest. Several onion growers began to report increased weed populations during this period of transitioning application methods, and now I know why.

These growers had been delaying applications until long after water was shut off, and their onion fields were drying out. Looking back, as I have recorded total readings throughout the exposure period of dozens of applications, we have found that areas of a field with 80 percent moisture have shown consistently higher concentrations of metam and longer duration of exposure than in soil with 50 percent moisture.

Overall, every one of “the five pillars” matters more than people think, and when adjustments are made and tracked over time in each category, the full potential of metam product use can be realized.

For more information, contact me at kyle.coleman@tkinet.com.