Agri-Stor Companies

Agri-Star Control Panel

Agri-Stor Companies helps growers take control of their onion storage with Gellert’s Agri-Star Control Panel. Since 1964, Agri-Stor has designed and sold thousands of Agri-Star panels for a wide range of post-harvest products. Through these years of application experience and university-based research, Agri-Stor Companies has developed its most user-friendly, advanced control panel yet. Features include a full-color, interactive touchscreen, easy-to-understand programming and internet capabilities with an intuitive app.

Fully adaptable to growers’ onion storages, the Agri-Star panel can handle everything including curing mode, burners, humidity, refrigeration, airflow, temperature, carbon dioxide levels, heat and lights. When growers match the Agri-Star panel with Gellert’s climate control equipment, their onions are wrapped in the perfect climate, extending their life and quality.

Chinook Equipment, Inc.

edp Electro-bagger

The Electro-bagger from edp Australia, model EB-2218-DF, is currently in stock. The machine has added control features on the touchscreen such as bag counters for each of the two preset programs. Users can adjust machine and belt speeds as well as monitor weight averages. The model also has pneumatic bag clamps and the ability to do bags or cartons with optional carton holders. A photo eye also can be used when bagging to ensure the belts won’t run without a bag in place.

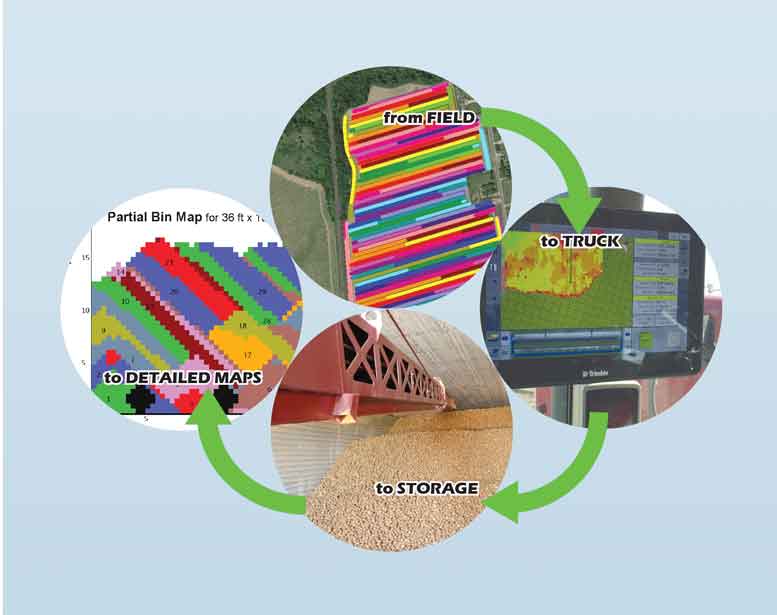

Greentronics

RiteTrace

Greentronics has added load-by-load field-to-storage tracking to its RiteYield root crop yield monitor product. The product, RiteTrace, is designed to automate harvest and storage data recording. This provides onion growers with a wide range of reports as well as field and 3D storage maps detailing where each load originated and is stored. Maps allow growers to link areas in storages and fields to better understand quality issues and improve crop management discussions and communications with buyers and processors.

Reports include yields by variety and field, and loads by field, storage and truck. Data points are date/time stamped, and maps and reports work well with GAP compliance.

Greentronics offers yield data integration with John Deere GS3 2630 and Trimble FMx and TMx monitors, allowing operators to view yield maps in real time. Yield maps offer visual insights to yield variability across fields and farms. Data are useful in calculating nutrient removal and generating variable rate application prescription maps.

IPL Macro

Plastic Bins

IPL Macro’s farm-to-harvest containers and totes are specifically designed to increase efficiency and reduce waste for growers and packers. Macro specializes in heavy-duty bulk containers and totes that can withstand the daily pounding that harvesting containers typically receive, while carefully protecting the vegetables inside. The highly engineered bins protect produce and reduce damage in the field and during transport.

Macro containers have smooth, nonporous surfaces that are easy to sanitize and won’t trap debris, breed bacteria or absorb chemicals. Plastic bins are lightweight and have consistent tare weights, as they do not absorb liquid. Macro’s plastic bins are HACCP and GAP compliant and FDA approved. Rounded corners and smooth interior reduce the risk of product scuffs, cuts and abrasions. Ventilation slots throughout the bins improve airflow, and heat absorption is reduced, which helps keep produce cool and increases the shelf life and quality.

Lee Shuknecht & Sons, Inc.

SP-132 Harvester

Lee Shuknecht & Sons, Inc.’s SP-132 is a self-propelled two-bed harvester that eliminates windrowing while simultaneously direct loading two beds, for a total production width of 132 inches using 47-inch chains. This low-maintenance mechanical harvester provides the highest percentage topping of green and/or dry onions of all Shuknecht’s onion harvesters while it harvests two to three tons per minute. Powered by a standard 190-hp Cummins engine, the solo operator seated in an air conditioned cab has complete control over blower speed, primary and rear elevator speeds, cutter bar speed and height and ground speed. The two-bed harvester features a 4-foot high-capacity boom and easily controlled front pickup elevators with spring-assist floats.

Available options include a moveable 4- or 5-foot dipper, rotating cab, stainless blower housing liners and a 240-hp engine. Digital readouts for the blower, primary chain and ground speed can be included, as well as hydraulic adjustment front elevator gauge wheels. Ground sync primary chain control, a posi-traction four-wheel-drive system and hydraulic trash chain drive can all be built into the SP-132.

The company also custom manufactures pull-behind models with the same quality and topping system to accommodate smaller onion growers.

Symach

Symach Rotax Palletizing Head

www.symach.nl/en/applications/5/onions.html

Symach has introduced the Rotax, a palletizing gripper head design to supplement the company’s existing lineup of machine features. This new design enables two onion filling machines to feed into one palletizing machine, saving customers additional machinery expense and floor space.

The Rotax palletizing head features a four-way design, allowing bags to be fed in no matter the existing head position, meaning the palletizing bucket doesn’t have to return to the home position to receive the next bag of onions.

Current Symach bag palletizing machines can stack up to 36 bags per minute (bpm); the Rotax head increases that rate to 46 bpm, a 25 percent gain.

Symach designs and builds bag palletizing solutions to suit customers’ needs. The company manufactures everything from pallet dispensers to high-speed wrapping systems, all custom designed to customer requirements.

Top Air, Inc.

Onion Topper Loader

The Top Air Onion Topper Loader continues to be a harvester of choice for growers around the world because of its gentle handling, superior removal of dirt/debris, and efficiency and reliability. It is available in one-, two-, three- and four-bed models with a variety of bed width configurations and options to fit operations of all sizes.

The XT (extra tall) models deliver high capacity while virtually eliminating bruising caused by rollback on the discharge elevator thanks to the tall profile.

Turbo Top

TT-268 Turbo Top Harvester

Turbo Top’s TT-268 is a self-propelled two-bed onion harvester. Green onions are one of Turbo Top’s specialties, allowing growers to start harvest earlier and control curing. Turbo Top is capable of day and night harvest and can work through the toughest conditions.

The TT-268 has dual 68-inch-wide pickup elevators for a total harvest pickup width of 190 inches, allowing onions to be picked up how they are grown without windrowing to reduce damage.

TT-268 is powered by a 410-hp John Deere Tier IV Final Package engine. It has infinite cab control of fan speed, primary chain speed, ground speed, load boom speed/movement, cutter bar height and front elevator depth. It also features an exclusive large topping area to eliminate weeds/debris and allow even the greenest tops to be sorted before topping.

Turbo Top comes in different models and has many options to fit growers’ needs.

Univerco

Two-Row Onion Harvesters

With 30 years of experience in building one-row onion harvesters, Univerco has introduced its new two-row onion harvesters.

The two-row models are available in both short-day and long-day onion versions. Both units have a similar harvest capacity per day, a steering axle to reduce turning radius on headlands and a system of three cameras so operators can easily monitor the key functions of the machine.

The short-day model has even more options available such as a sorting table, brushes under the topper table to keep the rollers clean at all times, and more angle and speed adjustments of the topper table. These improvements were made in an effort to minimize mechanical damage to onions.

Verbruggen

Palletizing Solutions

www.verbruggen-palletizing.com

Verbruggen has more than 30 years of experience in stacking onions and other agricultural products. A team of engineers is continually innovating and developing the company’s machines and software, allowing Verbruggen to offer effective palletizing solutions for agricultural products.

Machines can stack bags of onions in the range of 5 pounds to 120 pounds and offer high flexibility for future changes in product sizes and patterns. Systems can palletize single bags, bags in boxes and boxes/crates and can perfectly stable stack to the height of 8 feet. Machinery includes an easy-to-use operator station and is low maintenance for high up time. The company offers regionally based sales and service, as well as remote-monitored support.