|

Click to listen to this article

|

Investigating Practical, Effective Sanitizing Treatments to Reduce Cross-Contamination Risks in Post-Harvest Onion Facilities

By Joy Waite-Cusic, Sasha Nerney, Jason Racine and Sam Kilgore, Oregon State University

The Salmonella outbreaks linked to dry bulb onions in 2020 and 2021 led to initial high-volume product recalls. During the outbreak investigations, these recalls were expanded due to cross-contamination concerns between production lots.

When recalls are issued for processed foods, their scope is often limited due to the implementation of a master sanitation schedule and sanitation standard operating procedures within the manufacturing facility. These scheduled wet cleaning and sanitizing procedures establish “clean breaks” between production lots, minimize cross-contamination risks and support clear decisions about recall scope.

Post-harvest handling facilities that handle raw agricultural commodities typically manage the hygiene of their facilities following basic housekeeping procedures. For specific crops, like onions, it is imperative to keep the post-harvest packing areas dry to minimize the opportunity for microbial growth. In these facilities, basic housekeeping procedures focus on dry cleaning (e.g., sweeping, vacuuming) and fail to meet FDA’s expectations for a “clean break.”

Evaluating Dry Sanitation Options

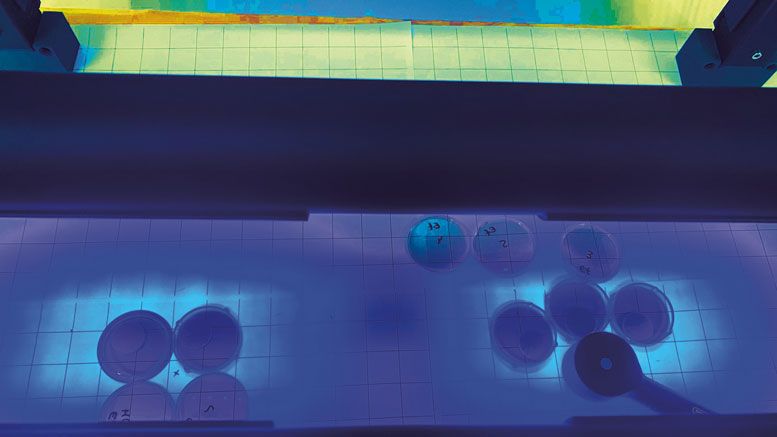

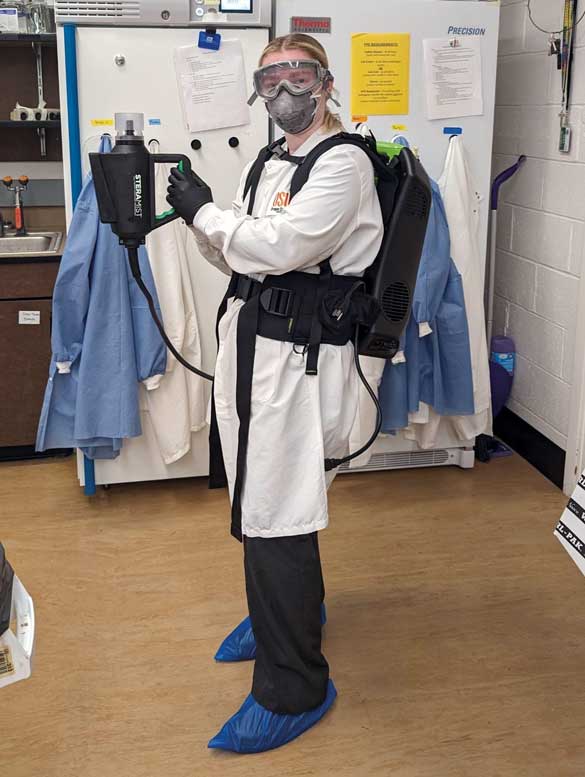

Oregon State University (OSU) researchers Joy Waite-Cusic, Stuart Reitz and Jovana Kovacevic have teamed up to investigate practical and effective dry sanitizing procedures that could be implemented by the onion industry to reduce the risk of cross-contamination between production lots. The Washington State Specialty Crop Block Grant Program is providing funding to support the evaluation of several dry sanitization options. Dry chemical sanitizers – specifically, alcohol-based and alcohol-quaternary ammonium compound combination products – were the initial focus of this research. Ongoing outreach with the onion industry identified interest in novel dry sanitation technologies, including UV-C and cold plasma (ionized hydrogen peroxide). These sanitizing approaches are being evaluated for their effectiveness against Salmonella on a variety of food contact surfaces present in onion facilities (e.g., plastic, wood, rubberized belts). The efficacy of sanitizers will also be determined for potential surrogate bacteria, Escherichia coli and Enterococcus faecium, to support later studies in commercial environments.

The efficacy of sanitation treatments will be coupled with pathogen prevalence estimates from various field trials and microbial transfer data collected by the OSU team as well as data shared by Linda Harris and Nitin Nitin at the University of California, Davis. This combination of data will be used to create an interactive model to estimate risk reduction by comparing current practices with the implementation of various dry sanitation options. The goal is to have this model ready for a pre-meeting food safety workshop at the Pacific Northwest Vegetable Association Conference in Kennewick, Washington, in November 2024.