|

Click to listen to this article

|

Irrigation Practices’ Impact on Water, Nitrogen and Energy Productivity in Desert Processing Onions

By Ali Montazar, Irrigation and Water Management Advisor, University of California Cooperative Extension

Given the essential role that sustainability and conservation play in successful farming today, the agriculture industry continues to search for ways to do more with less. A recent three-year research project in California is making a case for drip irrigation in desert processing onion production, with results suggesting benefits including water, nitrogen and energy savings.

Processing onions are produced throughout California with main production areas in Imperial, Kern, Fresno, Siskiyou and Modoc counties. In the Imperial Valley, a significant increase of acreage has occurred over the last decade, increasing from nearly 4,500 acres in 2013 to 14,500 acres in 2022.

Growers use different irrigation practices of furrow, subsurface drip and solid-set sprinkler to produce processing onions in the low desert. It is estimated that nearly 40 percent of desert processing onions are currently under sprinkler and drip irrigation. A University of California study aimed to evaluate the impact of the common irrigation practices on water, nitrogen and energy productivity in desert processing onion cropping systems (Fig. 1).

Field Experiments

The experiment was carried out in 15 commercial fields, including six fields under subsurface drip irrigation, six fields under solid-set sprinkler irrigation and three furrow-irrigated fields in the Imperial Valley over three crop seasons (2020-21, 2021-22, 2022-23). All fields consisted of 40-inch beds with six plant rows per bed with a spacing of 2.5 inches between planting lines. The driplines were installed in the center of beds at an average depth of 1.5 inches. The experimental fields were typically planted from early October to mid-November and harvested from late April to early June. The fields had a variable soil type with predominate soil texture from fine sandy to silty clay loam. Water, nitrogen and energy used; bulb weights; soil moisture; soil nitrate and soil salinity were monitored in each trial field.

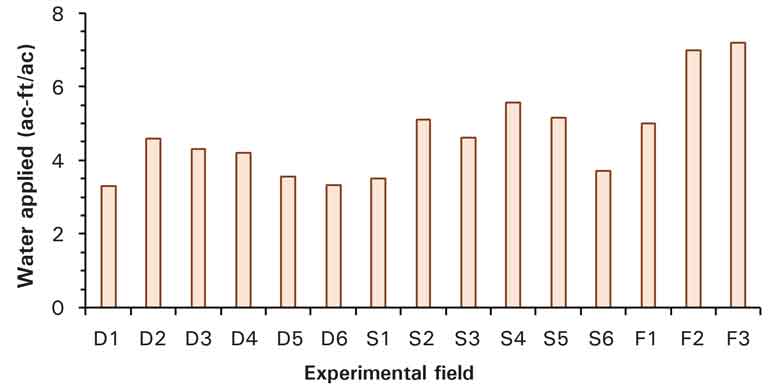

Water Conservation, Productivity

A wide range of seasonal irrigation water applied was observed across the experimental sites (Fig. 2). Irrigation water applied varied from 3.3 ac-ft/ac in a drip-irrigated field (field D6) to 7.2 ac-ft/ac in a furrow-irrigated field (field F3). The average seasonal water applied was 3.9 ac-ft/ac for the drip fields, 4.6 ac-ft/ac for the sprinkler fields and 6.4 ac-ft/ac for the furrow-irrigated fields. In other words, an average water conservation of 0.7 ac-ft/ac (~19 percent) and 2.5 ac-ft/ac (~60 percent) could be expected from converting sprinkler and furrow irrigation to drip irrigation in desert processing onions, respectively.

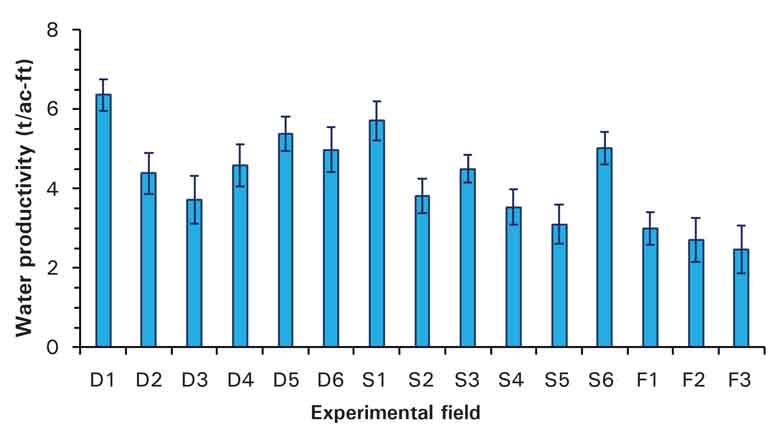

The irrigation water productivity, as the ratio of onion bulb weights to irrigation water applied, was calculated for each site (Fig. 3). A maximum and minimum water productivity of 6.4 and 2.5 t/ac-ft was found for processing onions across the experimental sites. A 14 percent greater water productivity was obtained for the drip-irrigated fields (4.9 t/ac-ft) than the sprinkler- (4.3 t/ac-ft) and the furrow- (2.7 t/ac-ft) irrigated fields. Negligible difference of bulb weights at harvest was observed between the two field categories of drip and sprinkler. Sites D1 and D6 were partially salt-affected, and their yield production could be impacted by salinity.

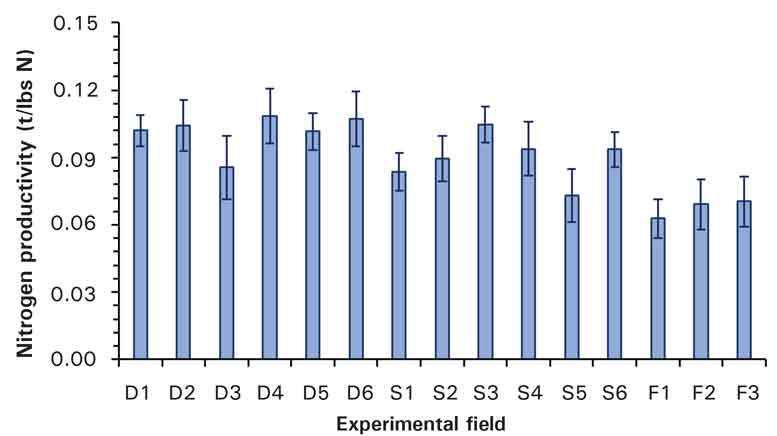

Nitrogen Application, Productivity

A wide range of nitrogen (N) application rates was observed across the trial fields, varying from 183 to 275 lbs./acre. N application rate was averagely 16.1 percent (in fields under sprinkler) and 40.4 percent (in fields under furrow) greater than the drip fields.

The nitrogen productivity was computed for each of the experimental fields as the ratio of onion bulb weights to N applied. The results demonstrated that the mean N productivity was greater at the drip-irrigated fields, averagely 13.1 percent greater than the sprinkler- and 50.5 percent greater than the furrow-irrigated fields (Fig. 4).

Energy Consumption, Productivity

Reducing energy consumption may reduce greenhouse gas emissions from an environmental aspect and energy costs from an economic aspect. While no energy is typically used for gravity furrow-irrigated fields, energy cost is one of the considerable components of production costs in pressurized irrigation systems. In the desert, growers typically use on-farm portable diesel pump stations for both drip and solid-set sprinkler irrigation systems (Fig. 5).

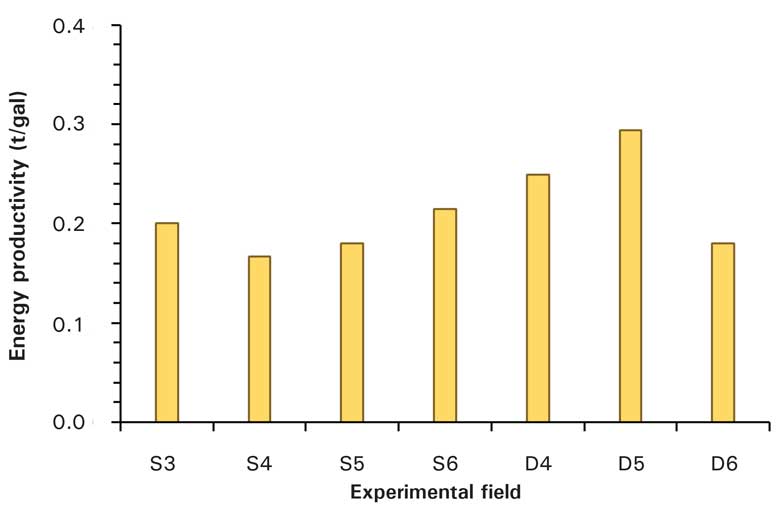

An analysis was conducted to evaluate energy consumption and productivity in the experimental fields of D4-D6 and S3-S6. The average fuel consumption varied from 87.3 to 118.2 gal/ac (with an average of 99.5 gal/ac) for the sprinkler-irrigated fields and ranged between 65.4 and 92.1 gal/ac (with an average of 78.3 gal/ac) for the drip-irrigated fields.

The energy productivity, as the ratio of onion bulb weights to diesel fuel used, was determined for these sites (Fig. 6). The results illustrated greater energy productivity values in the drip fields compared with the sprinkler fields. Averagely, this measure was 26.3 percent higher for the drip fields (0.24 t/gal and 0.19 t/gal in the drip and sprinkler fields, respectively).

Conclusions

Irrigation practice has a clear impact on resource use efficiency and water, nitrogen and energy productivity in desert processing onions. An average water conservation of 0.7 and 2.5 ac-ft/ac could be expected from converting solid-set sprinkler and furrow irrigation, respectively, to subsurface drip irrigation. Energy productivity of the onion fields under drip was averagely 26.3 percent greater than the fields under sprinkler.

Subsurface drip irrigation could cause salinity impacts on the topsoil. More frequent light irrigation events can be considered as a tool to manage salinity within the season. Summer salt leaching is a common practice in the desert region, which is highly recommend in drip-irrigated onion fields.

Greater water, nitrogen and energy productivity values could be considered as effective tools to increase net benefits of farming, along with enhancing efficiency as the main pathway to reduce the environmental risk in agricultural production.

Author’s note: Funding for this study was made possible by the California Garlic and Onion Research Advisory Board. I gratefully acknowledge the cooperating farms for their sincere collaborations during this study and for allowing the research staff to implement the project in their agricultural operations.