|

Click to listen to this article

|

By Prakriti Nepal, Youping Sun and Milena Oliveira, Department of Plants, Soils and Climate, Utah State University

The use of plant biostimulants is showing some promise as a potential means of helping onion crops thrive despite certain environmental challenges, according to new research at Utah State University.

Utah, the second driest state in the U.S., faces significant challenges in agricultural production due to its arid climate and unpredictable precipitation patterns. With approximately 95 percent of Utah’s water supply coming from mountain snowpack, the state’s agricultural sector is particularly vulnerable to drought conditions and climate variability.

Onions, cultivated on 1,600-1,800 acres in northern Utah, are especially sensitive to these environmental pressures. The crop’s shallow root system necessitates precise irrigation management for its optimal growth and development. Water stress during critical growth stages, particularly bulb formation, can significantly reduce onion yield and marketable quality.

Nitrogen management further complicates onion cultivation in Utah. While nitrogen is essential for plant growth, its excessive use can lead to delayed maturity and poor storage quality as well as environmental concerns such as nitrate leaching. Conversely, insufficient nitrogen limits growth and yield potential.

To address these challenges, there is a need for innovative approaches to onion cultivation in Utah that can address water scarcity, improve irrigation efficiency, and optimize nutrient management while maintaining or improving crop yields and quality. One promising approach is the use of plant biostimulants, natural or microbial products designed to enhance plant health and stress resilience. Humic substances, bacterial inoculants and other biostimulants have shown potential to improve water and nutrient use efficiency, enhance root development, and mitigate the effects of drought and nutrient limitations.

Research Results

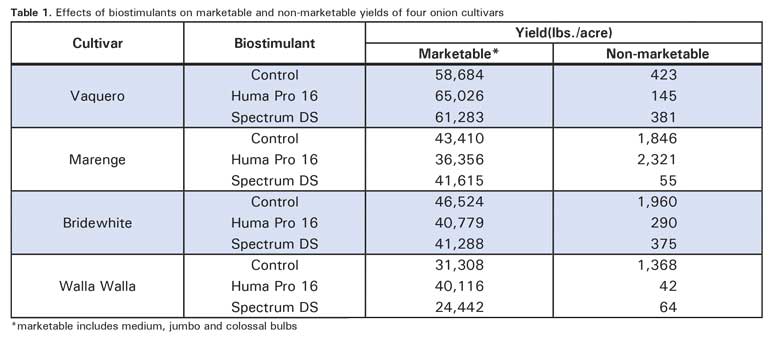

Research conducted at Utah State University investigated the effects of plant biostimulants on onion growth and production under varying environmental conditions. Field experiments began with careful soil preparation to ensure optimal planting conditions. Raised beds were formed and seeding was performed using a precision planter configured to plant two double rows spaced 3 inches apart, with 12 inches between the beds. The study began with greenhouse experiments testing seven biostimulants on Vaquero onion seeds, with Huma Pro 16 (Huma), a humic acid-based biostimulant, and Spectrum DS (Tainio Biologicals Inc.), a bacteria-based biostimulant, identifying as the most effective biostimulants in enhancing seedling growth. The subsequent field trials focused on four onion cultivars (Vaquero, Marenge, Bridewhite and Walla Walla) to evaluate the effects of biostimulants on onion growth and production. Bulbs were harvested in September, following standard farming practices typically used by growers in the region. The results were evaluated based on marketable yield (bulbs with a diameter of 2.25 inches or larger) and non-marketable yield (bulbs smaller than 2.25 inches in diameter).

Table 1 shows the effects of two types of biostimulants (Huma Pro 16 and Spectrum DS) plus a control (no biostimulant) on the four onion cultivars’ bulb productivity. Vaquero responded positively to Huma Pro 16, with marketable yields of 65,026 lbs./acre compared to 58,684 lbs./acre without the application of a biostimulant (control). Similarly, the non-marketable yield dropped from 423 lbs./acre (control) to 145 lbs./acre with the addition of Huma Pro 16. For Marenge, the control produced 43,410 lbs./acre of marketable onions, which was higher compared to the two biostimulant treatments. However, the addition of Spectrum DS showed promise by reducing non-marketable yield to 55 lbs./acre. For Bridewhite onions, marketable yield reached 46,524 lbs./acre under control conditions, while Huma Pro 16 and Spectrum DS produced only 290 lbs./acre and 375 lbs./acre of non-marketable onions, respectively. Walla Walla onions demonstrated a positive response with the application of Huma Pro 16 with a marketable yield of 40,116 lbs./acre while reducing non-marketable yield to only 42 lbs./acre. Similarly, only 64 lbs./acre of non-marketable onions were produced when Walla Walla onions were treated with Spectrum DS, compared to 1,368 lbs./acre without any biostimulant treatment (control).

The results underline the importance of using specific treatments for specific onion cultivars. Biostimulants like Huma Pro 16 and Spectrum DS can provide benefits, but their effectiveness varies depending on the variety, making it essential for farmers to choose the right approach for their specific crop.

In addition to biostimulant treatments, this study also evaluated onions under different irrigation and nitrogen levels: standard irrigation (100 percent evapotranspiration (ET)) versus deficit irrigation (75 percent ET) and standard nitrogen (150 lbs./acre) versus deficit nitrogen (100 lbs./acre). Although these trial components are not covered here, they provide insights into how water and nitrogen availability may influence onion growth and yield. More detailed information on the interactions of biostimulants and management practices will be reported at a later date.

Authors’ note: The project was funded by the USDA Agricultural Marketing Service Specialty Crop Multi-State Program in an agreement with Texas Department of Agriculture (TDA) and Texas A&M. The TDA and USDA agreement number is AM21SCMPTX1003, and the agreement number between TDA and A&M is TX-SCM-21-05.