Agri-Stor Companies

Agri-Star Control Panel

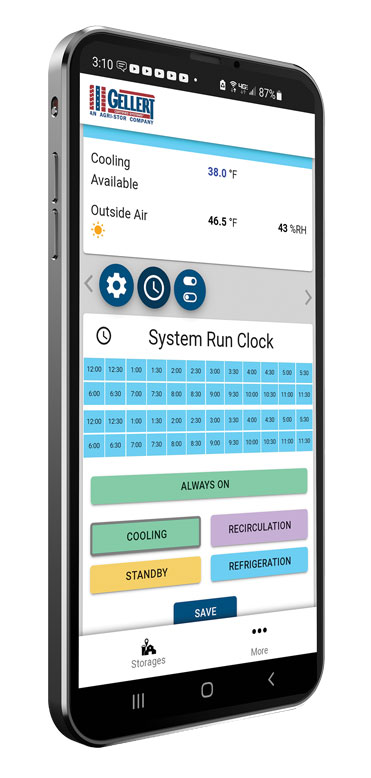

Agri-Stor Companies helps growers take control of their onion storage with Gellert’s Agri-Star Control Panel. Since 1964, Agri-Stor has designed and sold thousands of Agri-Star panels for a wide range of post-harvest products. Through these years of application experience and university-based research, Agri-Stor Companies has developed its most user-friendly, advanced control panel yet. Features include a full-color, interactive touchscreen, easy-to-understand programming and internet capabilities with an intuitive app.

Fully adaptable to growers’ onion storages, the Agri-Star panel can handle everything including curing mode, burners, humidity, refrigeration, airflow, temperature, carbon dioxide levels, heat and lights. When growers match the Agri-Star panel with Gellert’s climate control equipment, their onions are wrapped in the perfect climate, extending their life and quality.

Chinook Equipment, Inc.

edp Electro-bagger

The newest onion bagger from edp, model EB-2218-DF, is the most accurate and highest capacity bagger built by edp Australia. This machine will accommodate most any open-mouth bag on the standard 9-inch bag holder. Most customers in the U.S. use this machine for a range of bags from 20 pounds to 50 pounds.

Also available is the ability to fill cartons or crates with the optional carton-filling attachments. Speed control of both feed belts, pneumatic bag clamps, batch counters and monitoring of weight averages are among the standard features on the EB-2218-DF.

Ernst

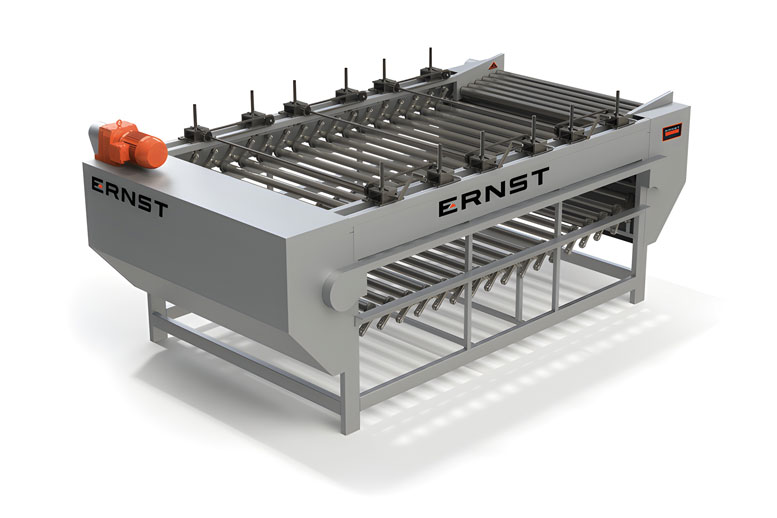

Ernst Expanding Roll Sizer

Ernst’s Expanding Roll Sizer has handled tonnage and throughput with caution, efficiency and precision for over 60 years. Even under the most challenging conditions, the Expanding Roll Sizer consistently achieves over 95% accuracy.

Kerian Machines

Kerian Speed Sizer

The Kerian Speed Sizer sorts onions by size quickly, accurately and gently. The constantly rotating rollers help the turning flaps align the onions with the rollers so that they are consistently sorted by size. The Kerian Speed Sizer is proven in use for whites, reds, golds, browns, Spanish, pearl and many other varieties of onions.

L&M Specialty Fabrication

TT-248 Turbo Top Harvester

Turbo Top’s TT-248 is a self-propelled two-bed onion harvester. Green onions are one of Turbo Top’s specialties, allowing growers to start harvest earlier and control curing. Day or night harvest? Turbo Top is capable of both. Adverse conditions? Turbo Top can work through the toughest of conditions.

The TT-248 has dual 48-inch-wide pickup elevators for a total harvest pickup width of 132 inches, allowing onions to be picked up how they are grown without windrowing to reduce damage.

TT-248 is powered by a 330-HP John Deere Tier IV Final Package engine. It has infinite cab control of fan speed, primary chain speed, ground speed, load boom speed/movement, cutter bar height and front elevator depth. Its exclusive large topping area eliminates weeds and debris and allows even the greenest tops to be sorted before topping.

Turbo Top comes in different models and has many options to fit growers’ needs.

Lee Shuknecht & Sons, Inc.

SP-132 Harvester

Lee Shuknecht & Sons, Inc.’s SP-132 is a self-propelled two-bed harvester that eliminates windrowing while simultaneously direct loading two beds, for a total production width of 132 inches using 47-inch chains. This low-maintenance mechanical harvester provides the highest percentage topping of green and/or dry onions of all Shuknecht’s onion harvesters while it harvests two to three tons per minute. Powered by a standard 190-hp Cummins engine, the solo operator seated in an air conditioned cab has complete control over blower speed, primary and rear elevator speeds, cutter bar speed and height and ground speed. The two-bed harvester features a 4-foot high-capacity boom and easily controlled front pickup elevators with spring-assist floats.

Available options include a moveable 4- or 5-foot dipper, rotating cab, stainless blower housing liners and a 240-hp engine. Digital readouts for the blower, primary chain and ground speed can be included, as well as hydraulic adjustment front elevator gauge wheels. Ground sync primary chain control, a posi-traction four-wheel-drive system and hydraulic trash chain drive can all be built into the SP-132.

The company also custom manufactures pull-behind models with the same quality and topping system to accommodate smaller onion growers.

Symach

Palletizing Equipment

Symach has a long history of palletizing onions and innovating to provide customized modular designs guaranteeing a high stacking rate with maximum flexibility. From 50-pound bulk and baled bags to complex Octabins, Symach has solutions to handle all customers’ palletizing needs.

Symach also offers options to stabilize the pallet at the end of the line, including wrapping and double stacking, and palletizing within the margins of the pallet to ensure ease of loading during the shipping process.

Top Air, Inc.

Onion Topper Loader

The 2024 XTR continues to be Top Air’s most capable onion topper loader. Available in two- or four-bed models, the XTR combines high capacity with superior handling. Featuring a high-performance rotary cutting system, this harvester outperforms in the most challenging harvest conditions on both short- and long-day onions.

Top Air is now taking reservations for 2025 models.

Unisorting

Onion Sort 3 & Uniq Onion

Unisorting, a brand of Unitec Group, develops and manufactures lines for onion sorting that combine high efficiency in the process and preservation of product integrity during each stage.

Onions Sort 3 and Uniq Onions are the latest systems, 100 percent developed in house, for external and internal quality selection of all varieties of onions. These solutions allow users to select the valuable or non-valuable characteristics of any type of onion without damaging the integrity of the product.

An accurate selection of external quality and internal quality, in addition to the detection of weight, optical size and shape, offers high performance solutions for every need. The dedicated technologies, semi-automatic or fully automated, are designed to offer the best possible result and give customers a highly reliable product without internal defects.

Univerco

Two-Row Onion Harvesters

With 30 years of experience in building one-row onion harvesters, Univerco has introduced its new two-row onion harvesters.

The two-row models are available in both short-day and long-day onion versions. Both units have a similar harvest capacity per day, a steering axle to reduce turning radius on headlands and a system of three cameras so operators can easily monitor the key functions of the machine.

The short-day model has even more options available such as a sorting table, brushes under the topper table to keep the rollers clean at all times, and more angle and speed adjustments of the topper table. These improvements were made in an effort to minimize mechanical damage to onions.

Volm Companies

VST30 Palletizer

The VST30 palletizer is designed to offer high stacking performance with minimal manual labor. It can reach a capacity of 22 bags per minute and will position product with the utmost accuracy. The automatic pallet in-feed ensures an automated process, which reduces labor costs.

Volm Companies offers a complete selection of end-of-line palletizing solutions. Volm engineers, constructs and installs Volmstack palletizing systems and has built an impressive portfolio that includes robotic, conventional, case stacking, bin filling and plate palletizing systems.