|

Click to listen to this article

|

By Stuart Reitz and Joy Waite-Cusic, Oregon State University

Dry bulb onions were traditionally considered a low-risk produce item for human foodborne diseases, but three recent outbreaks that have been linked to onions have challenged that view. In 2020 and 2021, two large outbreaks (> 1,000 cases per outbreak) of Salmonella were tied to red onions, and in 2024, an outbreak of E. coli O157:H7 was linked to slivered yellow onions served on hamburgers at multiple locations of an international fast food chain.

Investigations to identify sources and causes of foodborne disease outbreaks are challenging and often fail to definitively identify the particular product that was the source of an outbreak, let alone the specific cause of how that product became contaminated (for example, the use of contaminated irrigation water). There is an inherent lag between when people become ill, when an outbreak is declared, when potential food sources are identified, and when protective actions, such as recalls, can be implemented. Because of this inherent lag time, recalls are often implemented after much of the implicated product has passed through the chains of commerce.

Part of the belief that onions were “low risk” for foodborne diseases stems from characteristics of the crop, such as their papery wrapper scales and antimicrobial compounds produced in the bulbs. The wrapper scales of the bulbs are relatively impervious to water and protect the edible portion of bulbs from contamination; however, not all bulbs have intact wrappers, and they are not always completely removed during post-harvest handling. Onions do produce compounds (e.g., allicin and quercetin) that have antimicrobial activity when they are concentrated and purified; however, these defensive flavonoids are not active against Gram-negative bacteria, like E. coli and Salmonella, at the natural concentrations found in onions.

The onion industry has recognized the importance of proactively minimizing food safety risks. It has been a leader in produce safety efforts since the original draft Food Safety Modernization Act (FSMA) rules were issued over a decade ago. Even before the introduction of the FSMA rules, the National Onion Association (NOA) developed a best practices guide. In 2022, this guide was updated with the assistance of the International Fresh Produce Association (IFPA) and is available to NOA members online at onions-usa.org (Fig. 1).

Considering Water Applications

No definitive cause of either the 2020 and 2021 outbreaks was identified, but contaminated agricultural water was cited as a potential cause, and growers should be aware of the microbial quality of water they use for irrigation, pesticide applications and other pre-harvest operations.

Our research has shown that drip and furrow irrigation pose little risk for contamination as soil naturally filters out much of the bacteria from the water as it moves from the drip tape or furrow to the onion bulbs (Fig. 2a, b). Overhead water applications (e.g., sprinklers, pesticide applications) pose higher risks for contamination because water is directly applied to the plant, contaminating the surface of the onion and can also move down the leaves through the neck into the interior of the bulb (Fig. 3). Bacteria on the outer leaves of the onion die off during the curing process; however, bacteria in the neck or interior of the bulb will be unaffected by curing and may grow during curing or post-harvest storage.

Mitigating Cross-Contamination Risks

Regulatory investigations also identified cross-contamination in packing operations as a contributing factor in the outbreaks (Fig. 4). Over the last two years, we have been quantifying the risks for cross contamination between onions and food contact surfaces during packing operations. Onion packing requires a dry environment, and water is generally excluded from the packing facility to prevent microbial growth. While this is a good overall strategy, the lack of regular wet cleaning and sanitation prevents establishment of a “clean break” to prevent cross-contamination between production lots. The lack of clean breaks consequently promotes largescale recalls.

To help mitigate cross-contamination risks, we have been testing the effectiveness of “dry” alcohol-based sanitizers on surfaces commonly used in packinghouses. We have demonstrated that sanitizers with an alcohol content of ~60% or more reduce bacterial loads on conveyor belts and plastic surfaces but are only minimally effective on wood. Lower alcohol products (10-30% alcohol) should be avoided because they are ineffective and spread the bacteria, creating a larger surface area that is contaminated.

Looking Ahead

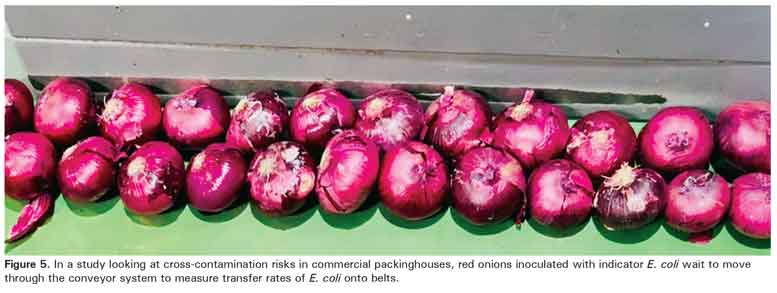

Upcoming research efforts will focus on using our research findings to model cross-contamination risks at commercial scale to quantify the potential benefit of using these sanitizers (Fig. 5). These models will be used to develop a web-based application so that industry members can explore and quantify the impact of implementing dry sanitation practices to support decision-making. Initial models will be shared at the joint National Onion Association and National Allium Research Conference in Hawaii in December 2025. We hope that these and other research findings will be incorporated into food safety plans for growers and shippers. Please reach out if we can be of assistance with your food safety plan.

There is more to learn about food safety practices in onion production, packing and fresh cut operations. In the meantime, we encourage growers to follow good agricultural practices to keep their crop as healthy and vigorous as possible. Minimizing pest and disease problems and other stresses are likely to reduce the risks of human pathogens contaminating onion bulbs. We encourage growers and packers to embrace produce safety as an integral component of their business because without this foundation, there could be no business to manage.