|

Click to listen to this article

|

HarvestEye

Harvest Monitoring Tool

Onion growers can now take advantage of crop insights tool HarvestEye, following the latest expansion of the system’s capabilities to work with more fresh produce.

Fitting to harvesting or grading equipment, HarvestEye is a cost-effective method to deliver visibility on the size, shape and mapping variability of crops as they are lifted.

Initially functioning with potatoes, HarvestEye announced its 2.0 system in 2023 with refreshed software and hardware to deliver faster crop measurement and more accurate data collection. HarvestEye brings to the onion market an advanced harvest monitoring tool for growers and packers that can help to make decisions during harvest to get the most from their crop, reduce waste and increase profit.

Industrial Ventilation, Inc. (IVI)

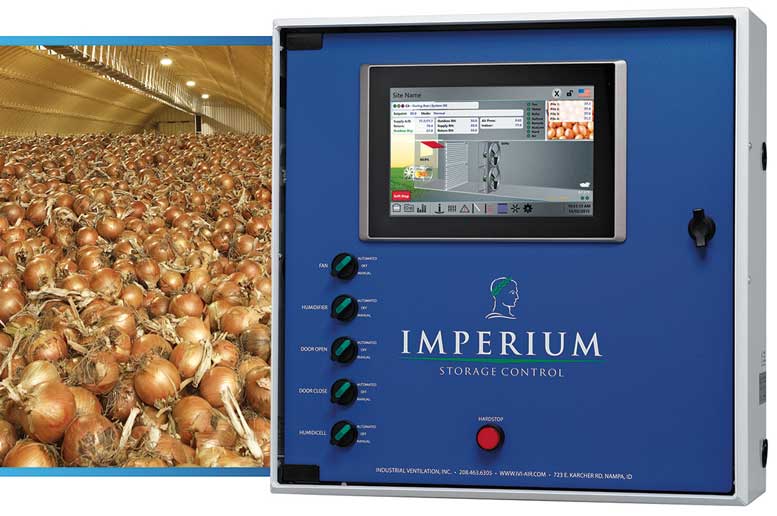

Imperium Storage Control Panel

IVI’s Imperium storage control panel directs optimal conditions for stored onions. Users can precisely control airflow, carbon dioxide, humidity and more and easily retrieve valuable historical data to aid in setting parameters. This powerful system for onion storage protection offers straightforward operation right at the user’s fingertips. The IVI app allows for off-site monitoring and control.

The Imperium storage control panel is made in the U.S.A. under the supervision of the engineers behind the innovations. The company’s eye is always on improvement and technological advances, driven by growers’ needs in working with IVI’s service and sales team.

L&M Specialty Fabrication

TT-248 Turbo Top

Turbo Top’s TT-248 is a self-propelled two-bed onion harvester. Green onions are one of Turbo Top’s specialties, allowing growers to start harvesting earlier and control their curing. Day or night harvest? Turbo Top is capable of both. Adverse conditions? Turbo Top can work through the toughest of conditions. The TT-248 has dual 48-inch-wide pickup elevators for a total harvest pickup width of 150 inches, allowing onions to be picked up how they are grown without windrowing to reduce damage.

Turbo Top can be equipped with John Deere Greenstar Precision GPS to allow the harvester operator to follow planter tracks and reduce operator fatigue.

TT-248 is powered by a 330-HP John Deere Tier IV Final Package engine. It has infinite cab control of fan speed, primary chain speed, ground speed, load boom speed/movement, cutter bar height and front elevator depth. A large topping area eliminates weeds/debris and allows even the greenest tops to be sorted before topping.

Micro-Trak

SprayMate Plus

SprayMate Plus rate control console is a plug-and-play replacement for out-of-date and discontinued rate controllers of most major brands. Customizable options and advanced features let users manage inputs with absolute peace of mind. Micro-Trak has adapter cables available to connect SprayMate Plus to existing systems, no matter the brand. Micro-Trak stands behind its products with a three-year limited warranty and is committed to providing repair service for consoles past the warranty period.

Symach

Palletizing Equipment

Symach has a long history of palletizing onions and innovating to provide customized modular designs to guarantee a high stacking rate with maximum flexibility. From 50-pound bulk onion bags to complex Octabins, Symach handles all customers’ palletizing needs.

The company also offers options to stabilize the pallet at the end of the line, including wrapping and double stacking, and palletizing within the margins of the pallet to ensure ease of loading during the shipping process.

Unisorting

Onions Sort 3 and UNIQ Onions

Unisorting is a brand of Unitec, an international group specialized in designing and manufacturing innovative solutions for processing, sorting, quality selection and packing of fresh fruits and vegetables.

Onions Sort 3 and UNIQ Onions are technological solutions in the company’s sorters that allow for external and internal quality selection, entirely conceived by the Unitec research and development team and manufactured 100 percent in house. The technologies offer significant cost savings at the defect detection stage and reliably classify products according to homogeneous quality characteristics so that they can be routed to the most suitable trade channel.

With its technological solutions dedicated to onions, Unitec wants to be close and strongly connected to the improvement objectives of U.S. packing houses. The company is also supported by four operating branches located in Washington, California and Oregon.

Verbruggen Palletizing Solutions

Palletizer VPM-14

verbruggen-palletizing.com/palletizer-machines/vpm-14

When it comes to reliability, speed, consistent stacking and secure pallet wrapping, Verbruggen’s VPM-14 has all of the bases covered. Specializing in stacking difficult products like onions, the VPM series of palletizers offer four-sided electric compression collars, articulating in-feed conveyors for maximum efficiency, and an enclosed stacking chamber with top and bottom compression to ensure a perfect stack every time.

Verbruggen’s VPM-14C allows for high-speed stacking of boxes and bags with the same machine. Users can switch between products with the touch of a button. Automatic pallet de-stacking and slip sheet placing, inline high-speed wrappers and standalone wrappers are all available options. Each machine is designed specifically for each individual application.

Verbruggen also offers stateside service, parts and after-sales support. Engineering, installation and commissioning are all performed directly by Verbruggen specialists.