Agri-Stor Companies

Agri-Star Control Panel

Agri-Stor Companies helps growers take control of their onion storage with Gellert’s Agri-Star Control Panel. Since 1964, Agri-Stor has designed and sold thousands of Agri-Star panels for a wide range of postharvest products. Through all these years of application experience and university-based research, Agri-Stor Companies has developed a user-friendly, advanced control panel. Features include a full-color, interactive touchscreen, easy-to-understand programming and internet capabilities with an intuitive app.

Fully adaptable to growers’ onion storages, the Agri-Star panel can handle everything including curing mode, burners, humidity, refrigeration, airflow, temperature, carbon dioxide levels, heat and lights. When growers match the Agri-Star panel with Gellert’s climate control equipment, their onions are wrapped in the perfect climate, extending their life and quality.

GroupAg

Vaapor Sanitizing Fog

Not all PAA thermal fogging is the same.

GroupAg developed the Jet-Ag thermal fogging application over 10 years ago. Since that first application, GroupAg has continuously developed its specially designed application equipment specifically for applying PAA chemistries in storages. GroupAg has done extensive laboratory testing as well as real-world bacteria and fungus testing before and after the application in storages, and thus has shown great results in sanitizing all types of crops in storage.

Jet Harvest Solutions

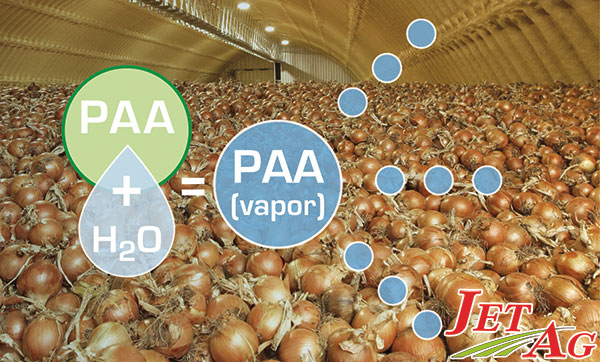

Jet-Ag

Jet-Ag’s original and unique patented formulation and process superheats and produces a thermal fog, which creates a vapor that permeates throughout the storage facility.

The patented technology utilizes the free radicals generated from superheated Jet-Ag into super microbial oxides which kills all microorganisms including bacteria, fungi and algae such as bacterial soft rot pathogens, Botrytis and black mold.

Jet-Ag also has a desiccant effect which creates a curative effect on the onion bulb in storage to help control disease. Jet-Ag can be applied at any time, but ideally upon completed storage of onions. Jet Harvest Solutions and Industrial Ventilation (IVI) offer application of this cost-effective treatment.

Pacific Building Systems

Steel Buildings

Proudly serving business owners, communities and farmers throughout the Pacific Northwest, PBS offers the experience and products to meet onion growers’ crop storage building needs. As experts in the industry since 1962, PBS designs, details, engineers and manufactures steel buildings.

The company offers multiple bulk storage methods, effective building optimization and quality building products. PBS buildings provide customized solutions for aspects regarding temperature control, ventilation and energy efficiency. Customers can incorporate mezzanines, crane bridges and solar panels in designs based on building requirements. The company also engineers and designs building additions and expansions to accommodate business growth and increase buildings’ functionality and durability.

Through the use of sound engineering, superior steel and seasoned experience, PBS provides reliable, high-quality, steel buildings customized to fit customer needs.

Suberizer

Suberizer Storage Systems

Suberizer offers turnkey storage systems that are engineered for maximum efficiency. As a proven industry leader in raw product storage, Suberizer’s commitment to innovation has impacted the way raw products are stored. Suberizer Curve and Envelope storage systems use AirEverywhere floors that ensure optimum airflow through the pile. This system minimizes loss, maintains quality and maximizes return.